MEMS Sensors

Overview

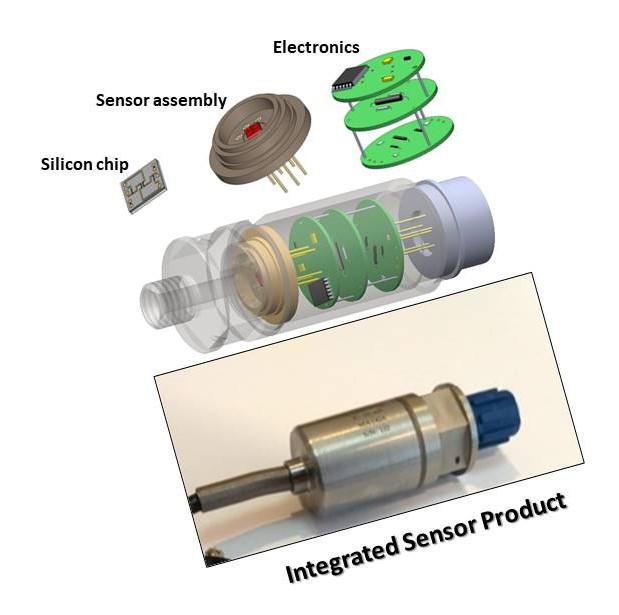

i2n now holds a technology to make Pressure Transducers for various applications. We are currently working on miniaturised sensing elements using MEMS-based technology to make a wide range of low to high pressure sensing devices based on piezo resistive transduction. Our products are built using high-end system integration facilities meeting the twin goals of high accuracy and repeatability. We can make different types of sensors; Differential, Absolute and Gauge, with customized packaging in an integrated product form. Our products can even qualify for high-end strategic applications.

We can provide sensor modules as per requirements, e.g. with uncompensated analog output or with compensated analog output housed in an assembly with integrated electronics.

Current Product Offering

Differential Pressure Transducer Assembly

Absolute Pressure Transducer Assembly

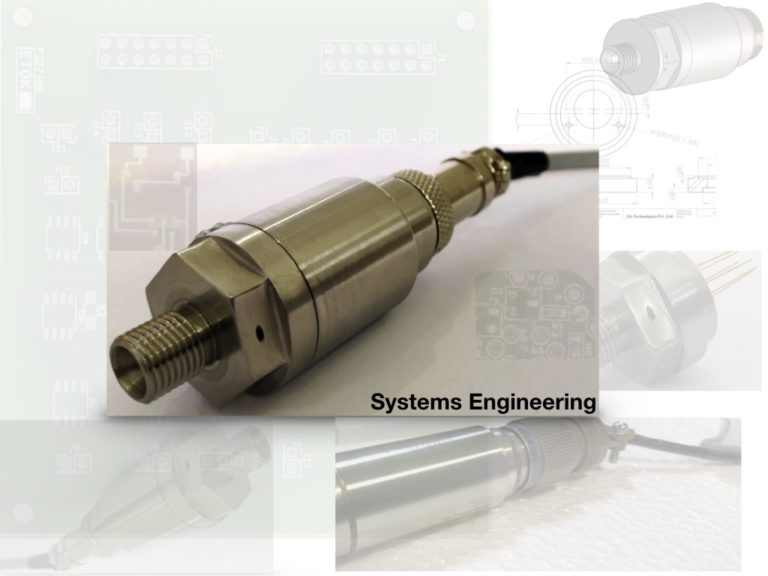

Systems Engineering

The technology used in the i2n Pressure Transducer product is based on MEMS based piezoresistive sensing elements housed in a precision micro machined glass to metal sealed mechanical enclosure. The product design ensures tolerance and acceptance of vibration and operability in extreme low to high temperature conditions.

Sensor Electronics

Sensor electronics to provide compensated analog output, is designed with high grade components and microelectronics. Typical pressure sensor signal conditioning needs are addressed by application specific ICs (ASICs). Hybrid integration techniques are used to ensure robust connections within the sensor packaging.

Quality Control and Inspection

The making of Pressure Transducers goes through a process of quality checks and inspections that are in line with the regulatory frameworks for the intended application. This begins with specific checks on inward materials and goods, continues with specific stage inspections and ends with quality checks against Acceptance Test Procedures. Every stage is documented and records are kept for later inspection. This process is followed for all stages of sensor manufacture, assembly and system integration.